MINERALSCAN 1500

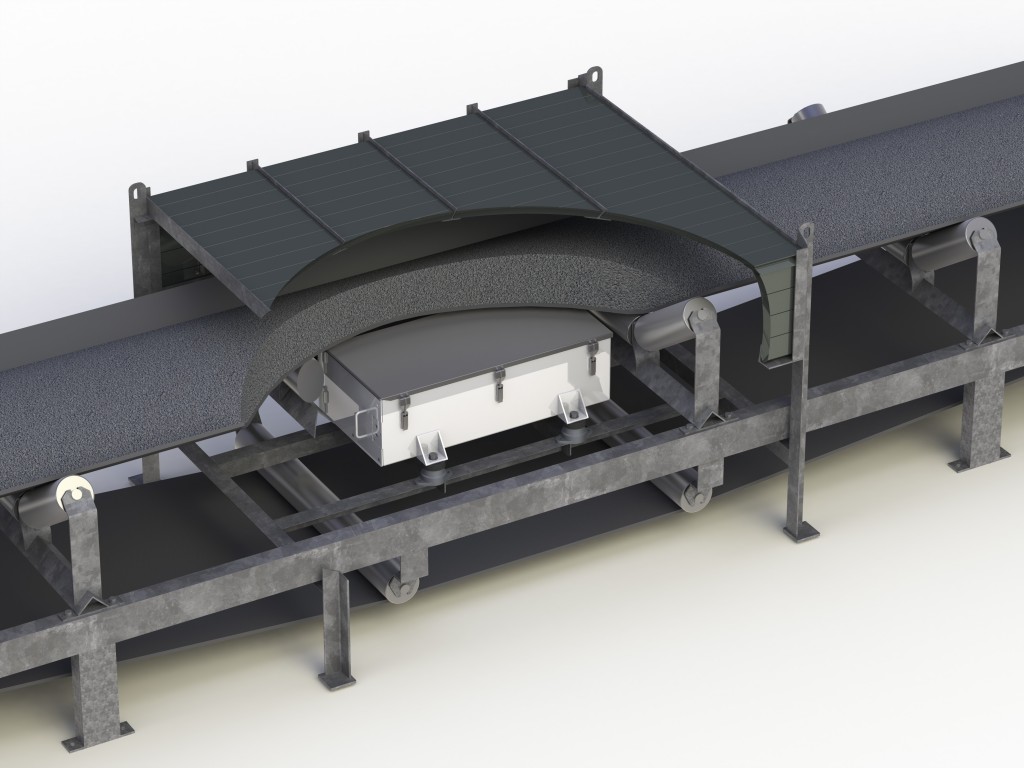

MINERALSCAN 1500 is an economical on-line ore monitoring system which is easily installed directly under production conveyor belts.

Real time ore quality data provides active process control, with timely information on ore quality to make decisions that maximise the value of the resource and minimise operating costs.

The system does not contain any nucleonic sources and therefore does not require site to obtain a radiation license for its use.

MINERALSCAN 1500 uses the natural gamma radiation (K, U, Th) signature of the material and known correlations with the composition to derive ore quality information, mainly for process control applications.

Typical applications include:

- Monitor run-of-mine uranium ore prior to stockpiling,

- Monitor other ores for uranium content, e.g. copper ores (IOCG type, etc),

- Potash content in ore or product,

- REE grade in ore where correlation with natural gamma exists (e.g. Th),

- Divert (bulk ore sort) or blend material based on real time measurements, e.g. used to recover gold in South Africa on a waste conveyor when U3O8 content (associated with the Au) was detected above background in conveyed increments. Sold as GOLDSCAN 1500 and payback on each unit achieved in a few weeks.

"When commodity prices were strong and rising, mining companies could afford minor inefficiencies in their plants. That is rarely the case in these days of lower-grade deposits, lower metal prices and economic pressure from every direction. “We have to do better with lower costs,” said Philip Thwaites, manager of process control for XPS Consulting & Testwork Services. “If you’re not efficient, you’re not going to be around. And our industry can be a lot more efficient.” According to Thwaites, measurement is the cornerstone of control and efficiency. “If you have a poor measurement, or no measurement, you can’t do good control,” he explained. But this is changing. More and more mining companies are conscious of improved measurements and endorsing control, automation and next-generation technologies. What is more, there has been significant progress in automated instruments recently. These measure crucial parameters in the processing circuit and equipment to allow operators to monitor and adjust process control as needed."

Alexandra Lopez-Pacheco, CIM, October 2015