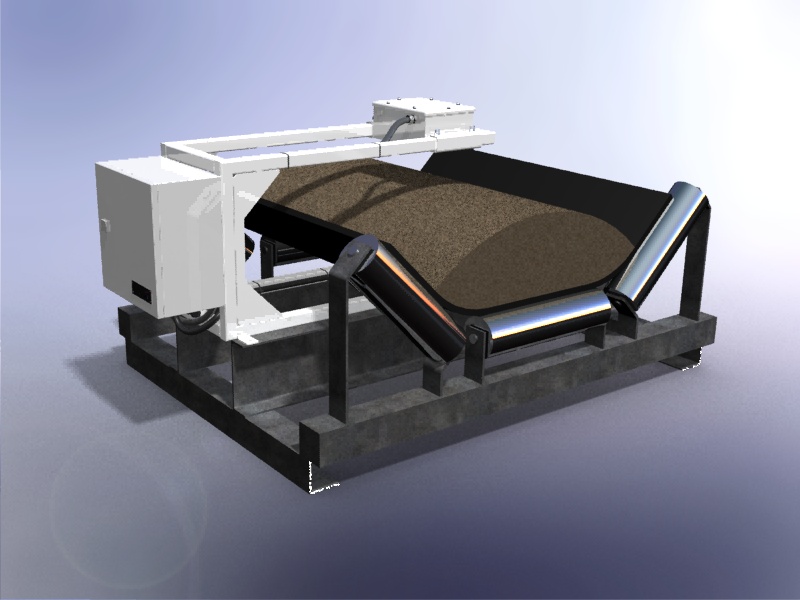

TBM 200 SERIES

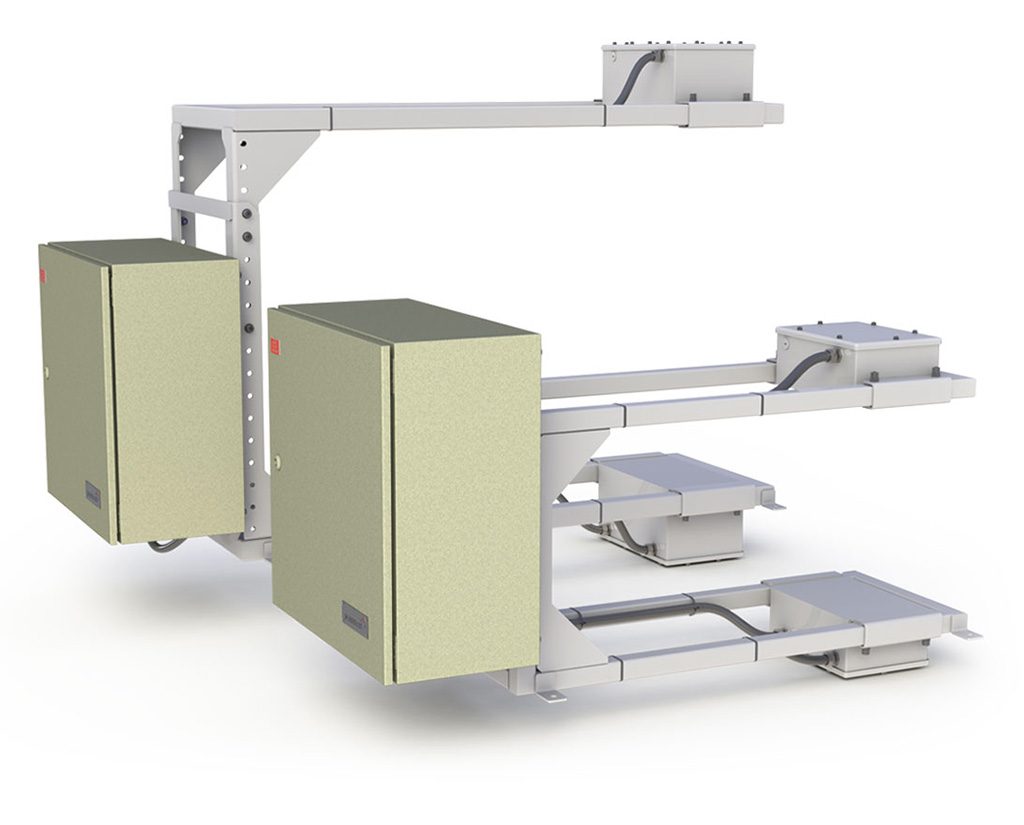

Real time analysis of moisture in a wide range of process materials provides active control over product quality, with timely information to make decisions that maximise the value of the product and minimise operating and maintenance costs. The TBM 200 Series of moisture monitors are the result of Scantech’s many years of experience developing microwave technology. They are easy to install, commission and calibrate, providing accurate results and stable, hassle-free operation.

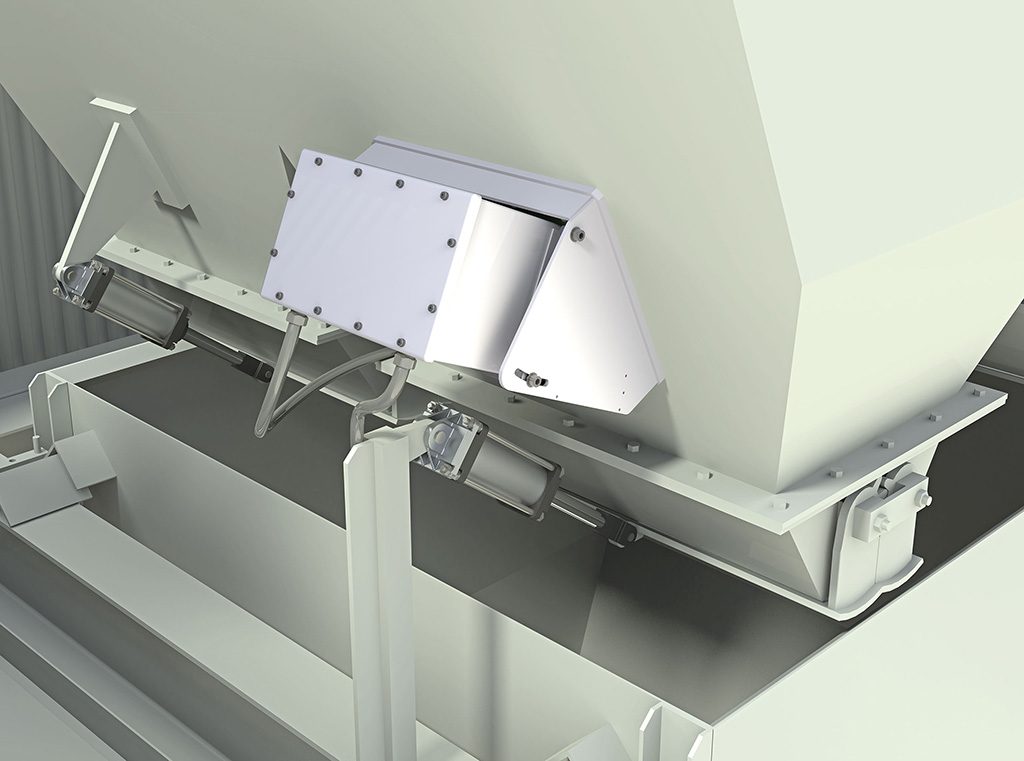

Measurement of microwave phase shift and attenuation enables reliable determination of moisture content, irrespective of particle size and belt speed.

Typical applications include:

- Monitor moisture content of fuels to determine Calorific Values,

- Monitoring feed moisture into a process, to determine dry tonnes, metal accounting, compliance to processing limits, e.g. major global gold producer increased ore throughput by 3% ($75M/year extra Au content) by increasing feed rate using measured moisture instead of relying on previous assumed moisture “factor”.

- Moisture content for additive control; reagents, binders, pH control, etc.,

- Monitor feed moisture in concrete batch plants for cement addition optimisation,

- Moisture content of potentially sticky/clumpy materials to improve flow and handling to avoid blockages, damage, spillage, downtime,

- Moisture in product to control dewatering circuits and dryer settings, reducing processing costs and optimising handling,

- Monitoring moisture for control of dust suppression systems,

- TML (transportable moisture limit) monitoring for transport of bulk materials to avoid liquefaction, etc.,

- Moisture as a proxy for clays and other components detrimental to processing.

There are a number of advantages of these analysers including:

- Provides accurate moisture analysis, custom calibrated to each installation,

- Rapid “online” results,

- Industry standard outputs,

- No radioactive source required,

- Available for conveyed flows, chute measurement, bales, bulky bags, etc.

Related Products

"Homogeneous fuel is a key parameter for ensuring high levels of efficiency when burning coal"

Norbert Spennrath Kima Echzeitsysteme, World Coal July 2012